OneSubsea™, an SLB joint venture, recently announced a contract award for its all-electric subsea production system, and John Macleod, vice president of technology and strategy at SLB OneSubsea, sees it as the onset of a tipping point.

“Large investments have been made across the industry to make this capability a reality, and we now see several projects on the horizon that use all-electric as their base case.”

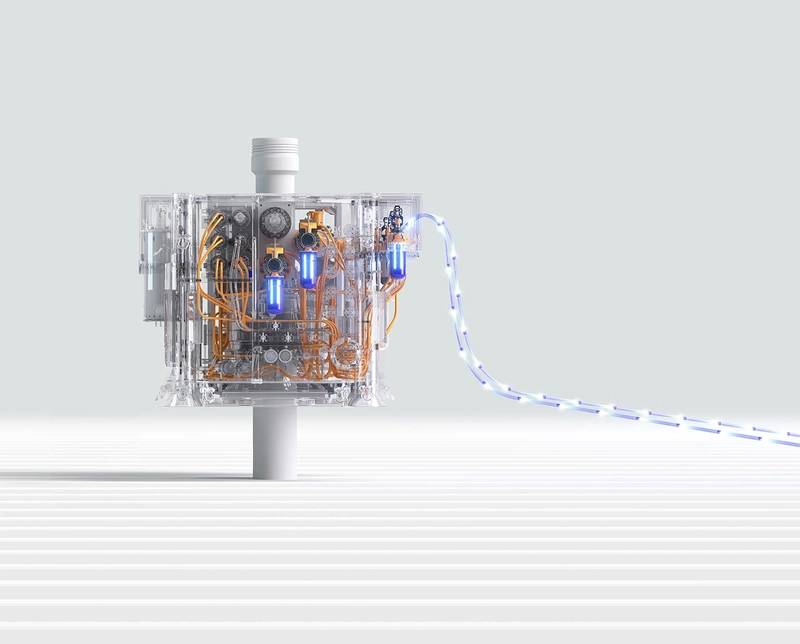

The first project is the recent contract award from Equinor for the front-end engineering design (FEED) of a 12-well, all-electric subsea production systems project in the Fram Sør field, offshore Norway. The solution will use SLB OneSubsea’s standard subsea tree design, upgraded with a fully electrified power, control and actuation system.

“You can only go so far by optimizing component-level performance,” says Macleod. “As we add to our electric capabilities toward a complete pore-to-grid solution, this will trigger further step changes in performance, enabling greater and greater system-level optimization capabilities and cost efficiencies.

“Additionally, an all-electric approach can help to overcome some of the limitations associated with legacy offshore power and control systems. Some of the cases we have looked at for tiebacks into mature infrastructure show an all-electric approach can help to enable the viability of these tiebacks.

“It will also enable the remote control of such assets during the operational phase. The resulting reduction in project cycle time and costs and the ability to produce previously inaccessible reserves can redefine an asset’s net present value for the better.”

All-electric systems are well suited to local energy generation and storage which can be an additional enabler to project viability. Also, electrification leads to reduction of surface infrastructure at the host facility, coupled with the reduction of hydraulics eliminating hydraulic power units and large topside reservoir.

In the future the integration with autonomous underwater vehicles, subsea wireless and subsea power solutions will support even more reduction of infrastructure topside.

“Electrification at a system level will drive simplification of integration with existing infrastructure, moving more to a plug-and-play model for infrastructure led (ILX) resources, for example,” says Macleod.

This is especially important for tiebacks into busy facilities, where plug-and-play power and communications result in much simpler topside modifications, much lower cost and much smaller environmental footprint rebuilding topsides.

The elimination of high-pressure hydraulic systems is expected to enable operators to go further and deeper, improving production and making even marginal fields more viable.

“Electrification is in some cases the only solution to achieve technical, commercial and operationally viable solutions for long distance developments. Using traditional systems, it will be much harder and costly to achieve both acceptable safety and operational performance compared with hydraulic systems during, for instance, shutdown and pressurization of the system. Digitalization of subsea assets facilitates more opportunities for conditioning monitoring, which allows for predictive maintenance and planned interventions or the potential to avoid equipment failure altogether.”

One of the key changes SLB has made is to go from a spring-operated on/off system to a battery-operated and motor controlled one, facilitating much better positional control.

“Ultimately, more control and more data enables realization of optimization that in time may lead toward more closed loop automation, as well as more cognitive workflows. This is becoming an extremely interesting area.”

Macleod points out that the benefits of increased electrification and instrumentation have been recognized across many industries, and history shows that once the benefits are demonstrated at scale, adoption accelerates. “That’s why we believe that the Fram Sør project could pave the way for accelerated industry-wide adoption of all-electric subsea technology, as it offers that industrial, scalable solution. It is built on a solid, proven technology platform, while offering lower cost, smaller footprint and simplified architecture. It is also a necessary piece in the overall digitalization effort of our industry.”